什么是深孔枪钻?

硬质合金枪钻也叫深孔钻,代表着先进、高效的孔加工技术。它不但可用来加工深孔(径长比1:250),而且也可用来加工浅孔(径长比1:1)。它由钻柄、钻杆、钻头三部分焊接在一起,中间有一通孔,适用于钻削铸铁、碳钢、铜、铝合金、合金钢等。枪钻将钻孔、镗孔、铰孔一次完成,一次走刀便可加工出高精度(IT6-8级)、精直线度(0.16-0.33mm/1000mm)、低粗糙度(Ra3.2-Ra0.1)孔。其钻削速度达到30-100米/分以上。

目前国内外在造船、汽车、发动机、机车、化工机械、油嘴油泵、矿山机械及液压件等行业得到广泛应用。 枪钻磨损后,需及时正确的刃磨,刃磨时必须在万能刃具磨床或专用刃磨机床上将枪钻装在专用夹具上进行刃磨,可选用粒度120左右的树脂金刚石砂轮进行刃磨,每次刃磨只修磨内外角的后刃面。必须保证正确的几何角度和刃尖位置。

我们可以根据客户的要求生产枪钻。详情请与我们联系。

What is GUN DRILLING?

Gun drilling is a kind of special deep hole cutting tool for the outer cuttings. The angle of the V type is 120°and for deep hole drilling, the V angle goes to 160. It must be used for the special machine tool.

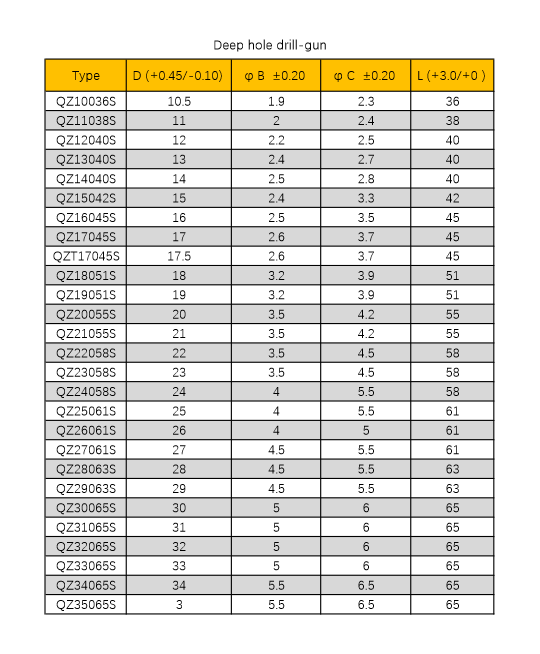

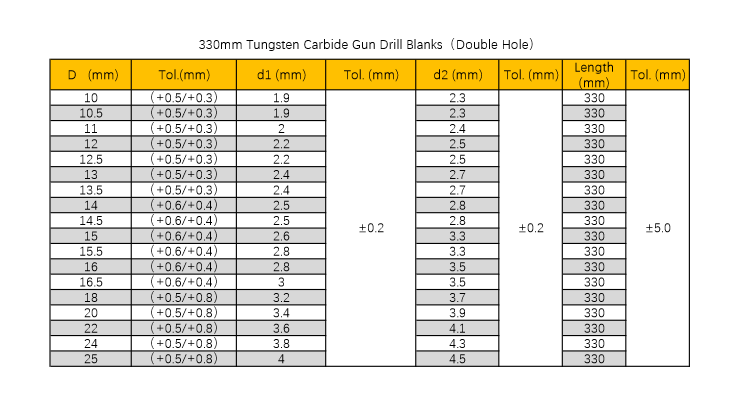

GWM is an expert in making tungsten carbide gun drilling, both blank and finished parts.Our gun drilling is effective in diameters from 10.5 – 35mm.The gundrilling process is able to drill deep holes beyond what is possible with conventional machinery and tooling such as twist drills, by using high pressure coolant for clean chip exhaust, even at extreme depths. We can also produce the gun drilling according to customers’ requests.